What is Pump Maintenance?

Regular pump maintenance helps prevent costly breakdowns and keeps your equipment running at peak efficiency. At Industrial Gear Works, we provide both corrective and preventative maintenance services:

Corrective Maintenance addresses urgent issues as they occur, restoring your pump to full working order.

Preventative Maintenance includes scheduled inspections and repairs designed to extend the life of your equipment and reduce the risk of expensive failures.

Common pump problems we solve include:

Corrosion

Bearing failures

Seal leaks

Worn shafts

Coupling misalignment

Impeller wear or damage

If your pump or its components are showing signs of trouble, our certified engineers are here to help. Call today to discuss your maintenance needs or request 24/7 pump service.

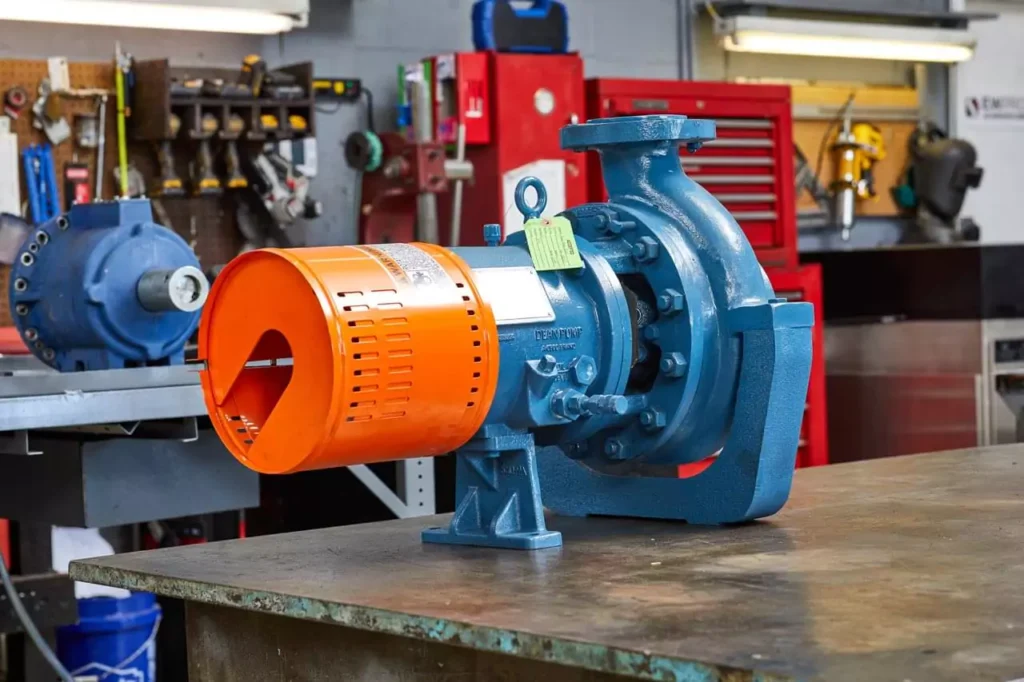

Industrial Pump Inspection and Repair

At Industrial Gear Works, we service a wide range of pumps, including Centrifugal Pumps, Positive Displacement Pumps, Terry Steam Turbines, Coppus Steam Turbines, Multi-Stage Pumps, and Boiler Feed Pumps. No matter the brand or type, our team has the expertise to restore your equipment to peak performance.

Our streamlined process makes pump inspection and repair straightforward:

Review your application needs through a spec, CAD drawing, or sample part

Disassemble and clean equipment for a detailed inspection

Identify the cause of failure and outline manufacturing requirements

Provide a thorough inspection report

Offer a free repair estimate before work begins

Restore equipment to OEM specifications, creating new components when needed

Deliver the repaired pump back to your facility, ready for operation

With decades of experience and a skilled team of technicians, Industrial Gear Works takes the stress out of pump maintenance and repair.

Cost-Effective Repairs to Keep Your Operations Running

Choosing repair over stocking spare pump parts is a cost-effective way to keep your operation moving without tying up capital. At Industrial Gear Works, our repair services save you money while minimizing downtime. When an unexpected failure occurs, our 24/7 Emergency Service is ready to restore your production quickly and efficiently. Every repair we complete goes through rigorous quality assurance testing to ensure long-lasting performance and reliability. With Industrial Gear Works, you can count on repairs that protect your investment and keep your operation running strong.

Reverse Engineering Pump Parts

At Industrial Gear Works, our reverse engineering process restores pumps and components to meet or exceed OEM standards while minimizing downtime:

Review – Examine your sample or CAD drawing.

Plan – Identify parts to recreate and select materials.

Optimize – Improve performance where possible.

Estimate – Provide a detailed scope and free quote.

Rebuild – Restore the pump with precision and reliability.

Benefits:

Access to obsolete components

Improved efficiency and performance

Reduced maintenance costs

Compatibility with any manufacturer

Reverse engineering is a cost-effective solution when new parts are unavailable, supply chains are delayed, or budget constraints prevent full replacement.